Lighter, Stronger, and More Sustainable Options

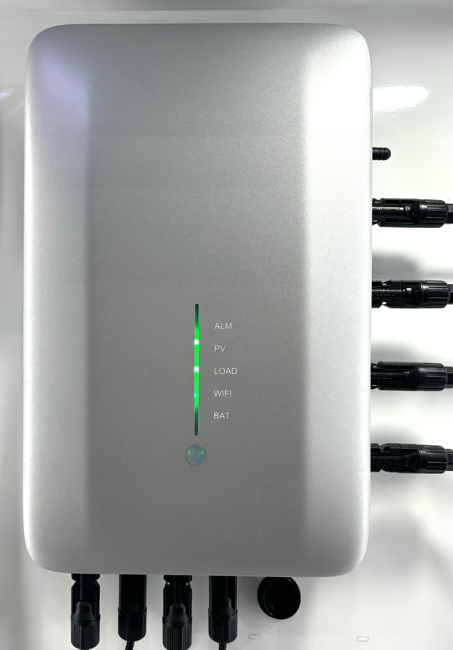

As the demand for renewable energy continues to soar, the need for innovative, reliable, and sustainable solutions for solar power systems grows more pressing. PV hubs, which connect solar panels to the rest of the electrical system, are a crucial part of this infrastructure. Traditionally, these hubs have been made from metals and plastics designed for durability and conductivity. However, as solar technology evolves, so too must the materials used in these hubs. The future of PV hubs is moving towards lighter, stronger, and more sustainable materials to optimize both performance and environmental impact.

The Need for New Materials in PV Hubs

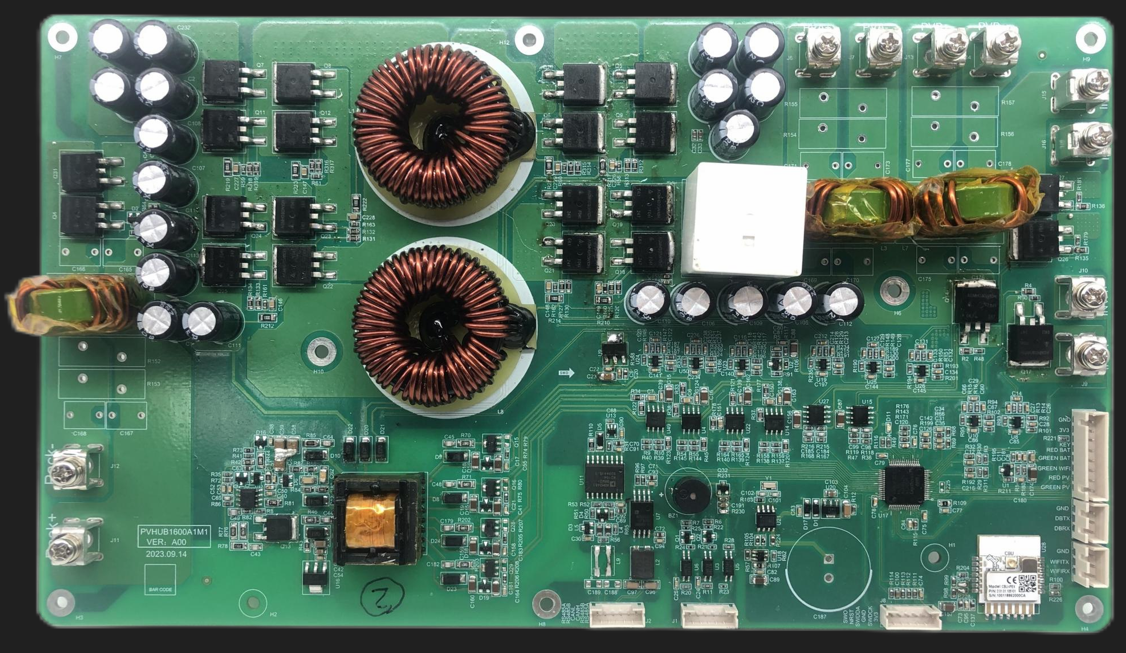

PV hubs are an essential part of solar power systems, connecting the solar panels to the rest of the electrical setup, including charge controllers, batteries, and inverters. Traditionally, these hubs have been made from metals like copper for excellent electrical conductivity and aluminum for its lightweight and corrosion-resistant properties. However, as solar power systems evolve, new challenges are emerging. These include increasing power requirements, better efficiency demands, and the need for greener, more sustainable manufacturing processes.

The future of PV hubs must meet several criteria:

Improved Durability: To withstand harsh outdoor conditions and last longer.

Increased Efficiency: To support next-gen MPPT (Maximum Power Point Tracking) systems and enhance the overall performance of solar energy systems.

Sustainability: To align with the eco-friendly nature of solar energy by reducing the carbon footprint of materials used in the hubs.

Lightweight Materials: Reducing Installation Time and Improving Mobility

One of the most exciting advancements in PV hub materials is the move toward lightweight materials. By reducing the weight of PV hubs, installation becomes quicker, easier, and more affordable. Lighter hubs are especially valuable in large-scale solar projects or residential installations where ease of handling is critical.

Key Lightweight Materials for PV Hubs:

Carbon Fiber Composites: Carbon fiber is an incredibly strong yet lightweight material that has become a popular choice in industries requiring both durability and minimal weight. It offers resistance to corrosion, extreme weather, and mechanical stress, making it ideal for PV hubs that need to endure years of outdoor exposure.

Advanced Aluminum Alloys: While aluminum has long been a go-to for PV hubs, newer aluminum alloys with a superior strength-to-weight ratio are emerging. These alloys maintain all of aluminum’s benefits, such as resistance to corrosion and good electrical conductivity, while being even lighter and stronger.

Magnesium Alloys: Magnesium is another lightweight alternative to traditional metals. With a higher strength-to-weight ratio than aluminum, it is ideal for high-performance solar hubs. Magnesium alloys can help reduce the overall weight of the solar power system while providing exceptional durability.

By using lightweight materials, solar installations can be completed faster and with less manpower, reducing labor costs and installation time. This also makes solar energy more accessible to both residential and commercial markets.

High-Strength Materials: Boosting Durability and Longevity

Durability is essential in outdoor installations where PV hubs are exposed to environmental stressors like extreme temperatures, high winds, UV radiation, and moisture. High-strength materials are essential to ensure that PV hubs continue to operate efficiently and maintain their integrity over time.

Key High-Strength Materials for PV Hubs:

Titanium Alloys: Titanium is known for its strength, resistance to corrosion, and ability to withstand extreme temperatures. It is highly durable and does not rust, making it an excellent option for PV hubs that will be exposed to harsh environmental conditions.

Stainless Steel: While not as lightweight as aluminum, stainless steel is incredibly strong and resistant to corrosion. It offers excellent structural integrity and is used in high-performance applications where durability is critical.

High-Performance Plastics: Certain heat-resistant plastics, such as polycarbonate and ABS, are now being used to encase electronic components in PV hubs. These plastics are lightweight, incredibly strong, and provide excellent resistance to UV radiation and environmental factors.

By incorporating high-strength materials, PV hubs are able to better handle the demands of modern solar power systems, including more powerful solar system charge controllers and MPPT solar power controllers, which require greater protection against weather and physical stress.

Sustainable Materials: Reducing the Carbon Footprint of Solar Systems

Sustainability is a core value of solar energy, and the materials used in PV hubs must align with this principle. As the solar industry continues to push for greener practices, sustainable materials are gaining prominence in the design of PV hubs. These materials help reduce the environmental impact of solar power systems, making solar energy an even more eco-friendly choice for consumers and businesses.

Key Sustainable Materials for PV Hubs:

Recycled Metals: Metals like aluminum and copper are highly recyclable and can be reused in manufacturing without degrading their quality. Using recycled metals in PV hubs can reduce the need for new mining and help lower the carbon footprint associated with material production.

Bio-Based Plastics: New innovations in biodegradable plastics and bio-based polymers have led to the development of environmentally friendly materials that can replace traditional plastics. These plastics are not only durable but also reduce the environmental burden of plastic waste at the end of their life cycle.

Recyclable Coatings: PV hubs often use coatings to protect components from the elements. Sustainable coatings made from organic compounds or low-emission materials are now being used to reduce the impact of production and disposal.

By adopting these sustainable materials, PV hubs contribute to a greener, more circular economy. These practices align with the eco-friendly nature of solar energy, ensuring that every component—from the solar panels to the MPPT solar power controller—is designed with sustainability in mind.

Towards a Smarter, Greener Future

The future of PV hub materials is an exciting one, with innovations in lightweight, high-strength, and sustainable materials paving the way for more efficient, durable, and eco-friendly solar systems. The integration of advanced materials ensures that PV hubs not only meet the growing demands of modern solar energy solutions but also contribute to reducing the environmental impact of energy production.

As solar energy continues to lead the charge toward a sustainable future, the materials used in PV hubs will play a critical role in ensuring the efficiency, longevity, and eco-friendliness of solar systems. With the rise of next-gen MPPT controllers, solar power charge controllers, and smart monitoring systems, PV hubs will evolve alongside these technologies, driving further advancements in solar energy.

By embracing innovative materials, the solar industry will not only improve the performance of solar systems but also help create a more sustainable, environmentally conscious future for all.